Condition Monitoring Equipment

Condition monitoring involves the continuous and on-time monitoring of the various industrial equipment and machineries such as vibration, temperature and sound. It is the more proactive means to preventive maintenance where any possible component defects are identified at an early stage. The most used and effective system is the vibration monitoring system and the vibration equipment that uses a set of tools used to measure one or more parameters in order to identify changes in the behavior of the machinery. In Fact, the main purpose of these systems is to help in scheduling the maintenance activities based on a process called Predictive Analysis.

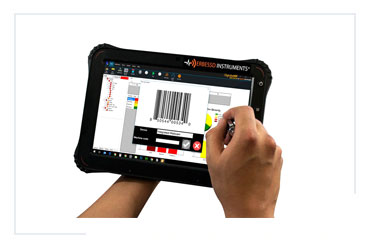

Vibration Analyzers have never been so portable. Our Triaxial Accelerometer communicates with mobile phones and computers in real time. So, Digivibe is able to generate FFT of more than 1 Million lines of resolution. Additionally, we created apps for Windows and iOS that complement and communicate with each other.