Flow & Level Instrument

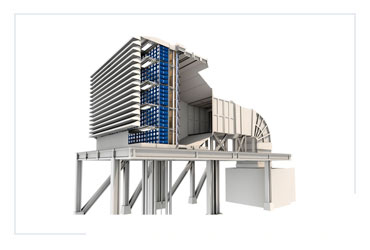

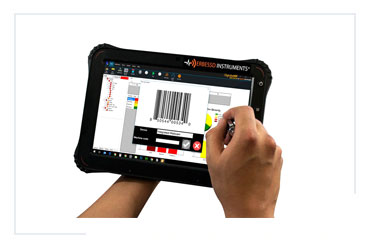

Industrial flow measurements include measuring the industrial fluids and gases covering water, natural gas, steam, mineral oil, chemicals, etc. Our flow and level instrumentations are custom engineered and built specifically with the latest technologies. Our products are best in class and are manufactured by the global leaders in pressure, level, and flow measurement technology. Our wide range of comprehensive solutions is based on high-quality metering systems for level measurement and flow measurement as well as application-oriented measurement systems.

The flow and level instruments are used to measure the mass or volumetric flow rate of the fluid or gas including Coriolis mass flowmeters, Electromagnetic flowmeters, Ultrasonic flowmeters, Vortex flowmeters, Differential pressure measurement, Thermal mass flowmeters.

FLOW MEASUREMENT SOLUTIONS

In applications that require traceable and guaranteed accuracy, inline ultrasonic sensors are preferred for use. Clamp-on ultrasonic sensors, on the other hand, are installed on the outer wall of the pipe and thus also enable temporary measurements or a retrofitting.

LEVEL MEASUREMENT SOLUTIONS

Pressure Measurement and Temperature Measurement Solutions

The robust thermometers are designed for use in demanding and safety relevant applications e.g. in the Chemical, Oil & Gas and Energy industry. The thermometers fulfills the corresponding safety requirements due to various certificates and tests. The use of a transmitter leads to higher accuracy and reliability in comparison to directly wired sensors.

OUR PARTNERED CLIENTS FOR FLOW & LEVEL INSTRUMENT

ABOUT CANOPUS

CanOpus Group is led by Professionally managed Team with more than

20+ years of Industry Experience.

CanOpus is a focused engineering solutions and services company helping the client with improved operational efficiency and reduced carbon footprint.

We are committed to helping clients with innovative industrial engineering solutions for improved operational efficiency.